A platform lift - how does it work?

A platform lift is more space efficient

Unlike a conventional elevator that has a cabin (car) moving up and down, a platform lift consists of a platform (floor) that moves vertically. The platform is attached to a drive unit that travels along guides (rails) in an enclosed shaft. In this way, a platform lift provides a more open feeling for the passenger, which is especially important if the lift is small (such as in a private home).

Platform lifts follow a more simple set of regulations

Platform lifts are covered by the European Machinery Directive, which is a simpler directive than the European Lift Directive for conventional elevators. To comply with the simpler Machinery Directive, a platform lift must meet a certain number of safety requirements. One such requirement is that the speed within Europe is limited. Another such requirement is that within Europe, one must hold the button when driving. These safety requirements are carefully balanced to provide as safe and secure a ride as possible without affecting the experience.

Screw and nut technology is the most popular

The most popular platform lifts have a drive system built on “screw and nut technology.” The technology relies on an electric motor causing a nut to rotate along a long special drive screw. When the nut rotates, the lift moves up or down. There are also other techniques for driving platform lifts. Such solutions can, for example, be hydraulic or chain-based. Since these technologies often produce more noise or may have leaking oil, they are used increasingly rarely.

A platform lift is a very safe choice

A platform lift is one of the safest and most reliable lifts to ride in. This is due to the many safety features in the lift. Some examples of this are the required dual safety brakes, safety edges that prevent anyone from getting caught, emergency opening features, and various solutions for battery backup in case of power failure. Platform lifts have been mostly used in public settings such as wheelchair access in schools, shops, or other public buildings for the past 30 years.

The reason they have become so popular is that during the 1990s, the EU implemented new non-discrimination laws and regulations for people with disabilities, which created a huge demand for smart and cost-effective lifts. Sweden was early in following the regulations, and therefore Sweden has become strongly associated with platform lifts from various manufacturers.

Primarily used for buildings up to 6 floors

Platform lifts are primarily used in buildings up to 6 floors or a maximum of 15-20 meters in lifting height. The lifts can typically carry loads from 250 kg up to 1000 kg and come in many different sizes to suit various types of buildings.

Advantages with platform lifts

Platform lifts are very popular for several reasons. Among other things, they are practically ‘all-inclusive‘ with a shaft designed as building blocks of glass or shaft panels. This way, no money needs to be spent on building an external shaft, and likewise, no special doors are needed on each floor. In addition to this, some of the main advantages compared to hydraulic lifts or traction lifts are that platform lifts do not require a machine room, safety space beneath the lift (read more about pit), or safety space above the lift. Overall, it is much easier to install a platform lift, and the costs for construction work become much lower.”

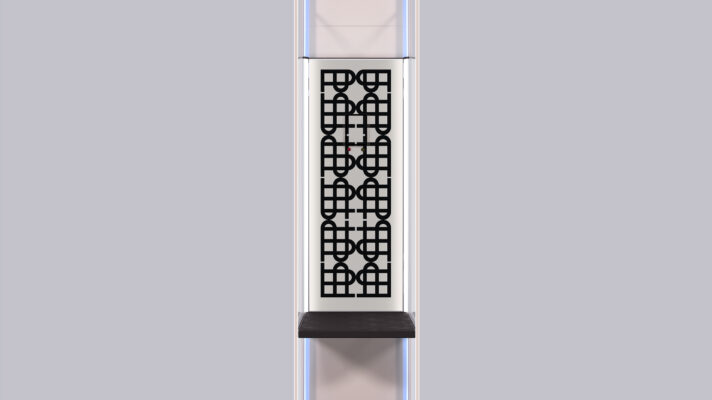

Platform lifts and SWIFT

With SWIFT, we have endeavored to merge the smooth ride and luxury of a traditional elevator with the smart, simple, and safe features of a screw-driven platform lift. The result is a luxurious, energy-efficient, all-inclusive lift that is affordable, compact, and easy to install. Perfect for private homes. We call this a home lift.