What drive motor does SWIFT use?

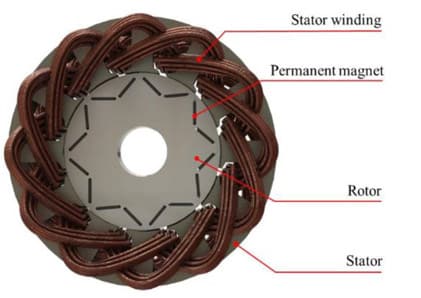

SWIFT uses the same type of advanced elevator motor as Tesla and other electric vehicles – a so-called IPM (Interior Permanent Magnet) SynRM (Synchronous Reluctance Motor). This type of electric motor elevator system is more advanced than a conventional induction motor and stands out for its high efficiency, performance, control capabilities, and long-term reliability.

Some key Differences:

- Construction and design

A conventional induction elevator motor relies solely on electromagnetic induction to create a rotating magnetic field in the rotor. It does not contain permanent magnets.

An IPM SynRM electric motor elevator has permanent magnets embedded in the rotor. These magnets generate a magnetic field that interacts with the stator’s field to produce motion. - Higher efficiency

The presence of permanent magnets in the rotor enhances the efficiency of IPM SynRM motors, especially at partial loads and low speeds. This results in reduced energy consumption and lower operating costs over time. - Better performance

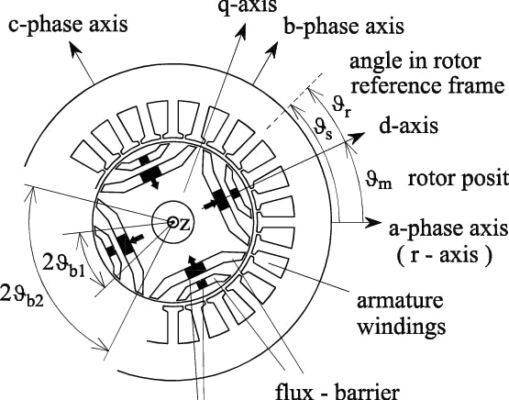

IPM SynRM motors provide higher torque density, better speed control, and smoother operation. These characteristics are ideal for elevator motor applications, offering enhanced efficiency across various speeds and loads. The improved control also provides a more comfortable and quiet ride experience.

-

More advanced control

Due to the embedded permanent magnets, IPM SynRM motors require advanced control methods such as field-oriented control (FOC), allowing precise control of speed, torque, and efficiency.

For this purpose, SWIFT has developed a unique motor controller. In comparison, conventional induction electric motor elevators can be controlled using simpler voltage or frequency-based systems.

SWIFT IPM SynRM motor + SWIFT motor controller + SWIFT battery pack = key advantages:

- Smoother acceleration and deceleration of the lift, with more precise landings

- Speed control through the user-friendly touch display

- Motor management system calculates the weight of passengers or luggage

- Regenerative braking feeds energy back into the batteries when the lift travels downward – offering energy savings and making every 4th trip “free”

- The lift remains fully operational even during a mains power failure, thanks to our battery-powered anti-trap feature

- With battery support, all lifts run on standard 1-phase power – reducing peak demand requirements