Motor penggerak apa yang digunakan SWIFT?

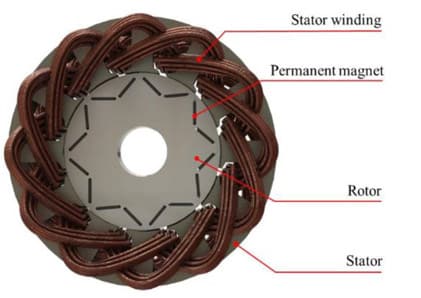

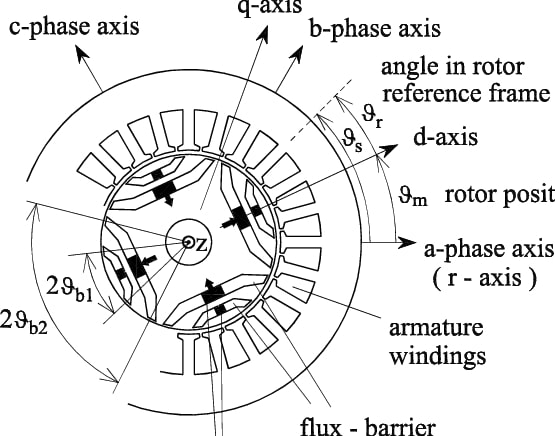

SWIFT menggunakan jenis lift motor berteknologi tinggi yang sama seperti yang digunakan pada Tesla dan mobil listrik (EV) lainnya, yaitu IPM (Interior Permanent Magnet) SynRM – Synchronous Reluctance Motor. Teknologi motor lift ini jauh lebih maju dibandingkan motor induksi konvensional, dengan keunggulan pada efisiensi, performa, kemampuan kontrol, dan keandalan.

Berikut beberapa perbedaan pentingnya:

1. Konstruksi dan Desain

Motor induksi konvensional sepenuhnya mengandalkan induksi elektromagnetik untuk menciptakan medan magnet berputar pada rotor. Jenis mesin lift ini tidak menggunakan magnet permanen pada rotornya.

Sebaliknya, lift motor IPM SynRM memiliki magnet permanen yang tertanam di dalam rotor. Magnet ini menghasilkan medan magnet yang berinteraksi dengan medan magnet stator untuk menciptakan gerakan yang lebih efisien dan stabil.

2. Efisiensi Lebih Tinggi

Keberadaan magnet permanen pada rotor meningkatkan efisiensi motor lift IPM SynRM, terutama pada beban parsial dan kecepatan rendah. Hal ini menghasilkan konsumsi energi yang lebih rendah serta biaya operasional yang lebih hemat.

3. Performa Lebih Baik

Stair lift motor berbasis IPM SynRM menawarkan karakteristik performa yang unggul, seperti kepadatan torsi yang lebih tinggi, kontrol kecepatan yang lebih presisi, serta operasi yang lebih halus dan senyap.

4. Sistem Kontrol Lebih Canggih

Karena menggunakan magnet permanen, lift motor IPM SynRM memerlukan sistem kontrol yang lebih maju, seperti Field-Oriented Control (FOC). Sistem ini memungkinkan pengaturan kecepatan, torsi, dan efisiensi secara presisi dalam berbagai kondisi operasional. Untuk mendukung hal ini, SWIFT mengembangkan pengendali motor khusus.

Sebagai perbandingan, motor induksi konvensional umumnya masih menggunakan metode kontrol yang lebih sederhana, seperti kontrol tegangan atau frekuensi.

SWIFT IPM SynRM motor + SWIFT motor controller + SWIFT battery pack = Keunggulan Maksimal

- Akselerasi dan perlambatan lift yang jauh lebih halus, serta pendaratan yang lebih presisi.

- Pengguna dapat mengontrol dan memilih kecepatan lift melalui layar sentuh.

- Sistem manajemen mesin lift mampu menghitung berat penumpang atau barang secara akurat.

- Energi yang dihasilkan saat lift melakukan pengereman (turun) dapat dikembalikan untuk mengisi baterai, menghasilkan penghematan energi hingga “setiap perjalanan ke-4 menjadi gratis”.

- Dengan daya dari baterai, lift tetap dapat beroperasi penuh meskipun terjadi pemadaman listrik (anti-trap feature).

- Penggunaan baterai mengurangi kebutuhan daya puncak, sehingga semua lift SWIFT dapat dijalankan dengan listrik 1-phase.